The Importance of the Main Machine in the HP300 Multi-Cylinder Hydraulic Cone Crusher

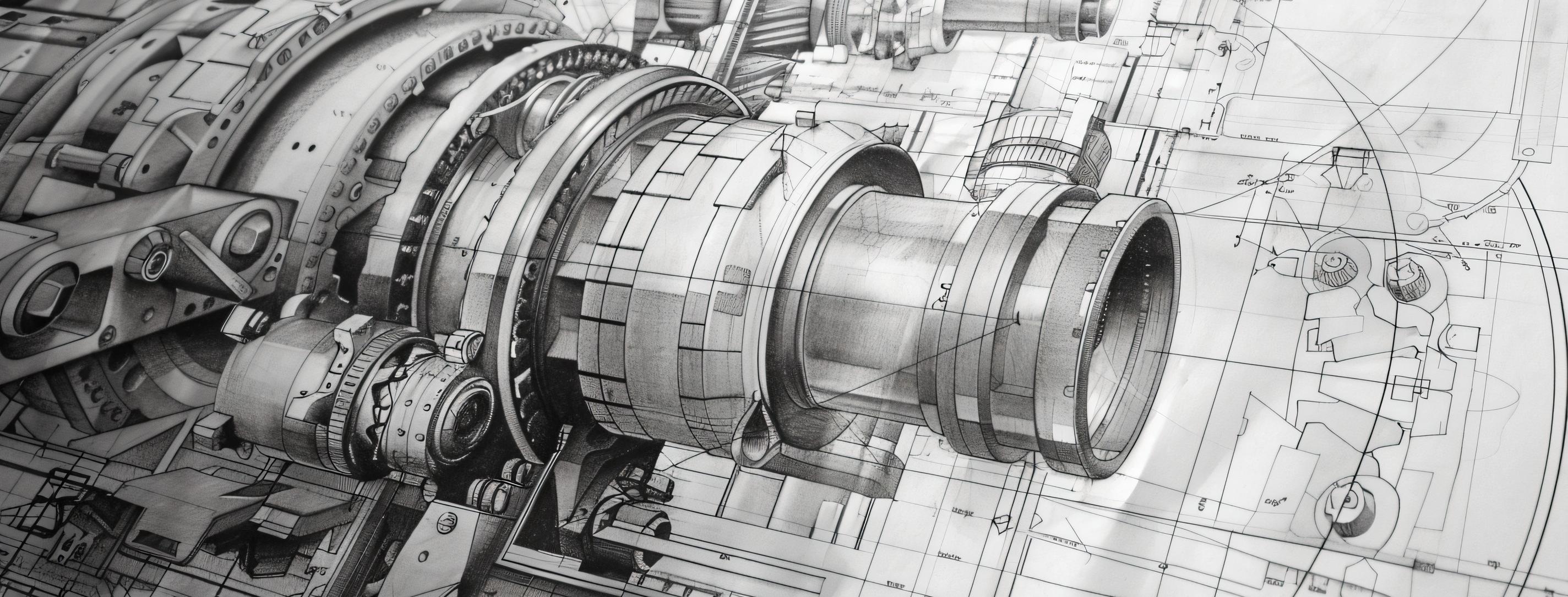

The HP300 Multi-Cylinder Hydraulic Cone Crusher stands as a cornerstone in modern mining, construction, and aggregate industries, revolutionizing material processing through its advanced engineering. At HP300 Cone Crusher's core, the main machine—comprising the hydraulic system, crushing chamber, and structural framework—drives efficiency, durability, and sustainability, making it indispensable for high-performance operations.

Central to the HP300 Cone Crusher’s superiority is its multi-cylinder hydraulic system. Unlike traditional crushers, this innovation enables precise adjustment of the crushing gap and automatic overload protection. The hydraulics facilitate real-time responsiveness, optimizing particle size consistency while safeguarding the machine from damage caused by uncrushable materials. This automation reduces manual intervention, enhancing operational safety and productivity.

Structurally, the HP300 Cone Crusher’s robust design ensures exceptional durability. Constructed with high-strength alloys and precision engineering, its main frame and components withstand extreme pressures and abrasive materials. This resilience minimizes wear-related downtime of cone crusher, lowering maintenance costs of cone crusher and extending service life of cone crusher—a critical advantage in harsh industrial environments.

The HP300 Cone Crusher’s crushing chamber design further underscores its importance. Optimized geometry and high rotational speeds ensure superior reduction ratios and throughput capacity. By producing uniformly shaped aggregates, the HP300 Multi-Cylinder Hydraulic Cone Crusher enhances the quality of end products, meeting stringent specifications for infrastructure projects, from road construction to concrete production.

Energy efficiency is another hallmark. The HP300 cone crusher’s hydraulic system and optimized kinematics reduce power consumption per ton of processed material, aligning with global sustainability goals. Lower energy use translates to reduced operational costs and a smaller carbon footprint, appealing to eco-conscious industries.

Moreover, the integration of smart control systems allows operators to monitor performance metrics in real time, enabling data-driven adjustments for peak efficiency. This connectivity aligns with Industry 4.0 trends, positioning the HP300 as a future-ready solution.

Versatility amplifies its value. The HP300 adapts to diverse applications, from secondary crushing in mining operations to producing railway ballast. Its flexibility supports rapid project scalability, catering to varying production demands.

In conclusion, the HP300’s main machine is pivotal in modern material processing. By harmonizing hydraulic precision, structural resilience, energy efficiency, and smart technology, it elevates productivity while reducing costs and environmental impact. As industries prioritize efficiency and sustainability, the HP300 remains a vital asset, driving progress in infrastructure development worldwide.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/